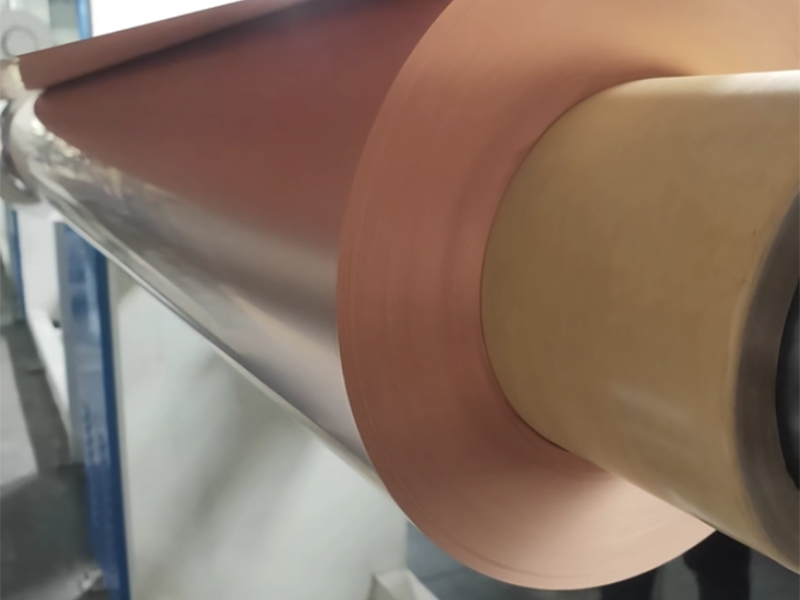

Электролитическая медная фольга для экранирования

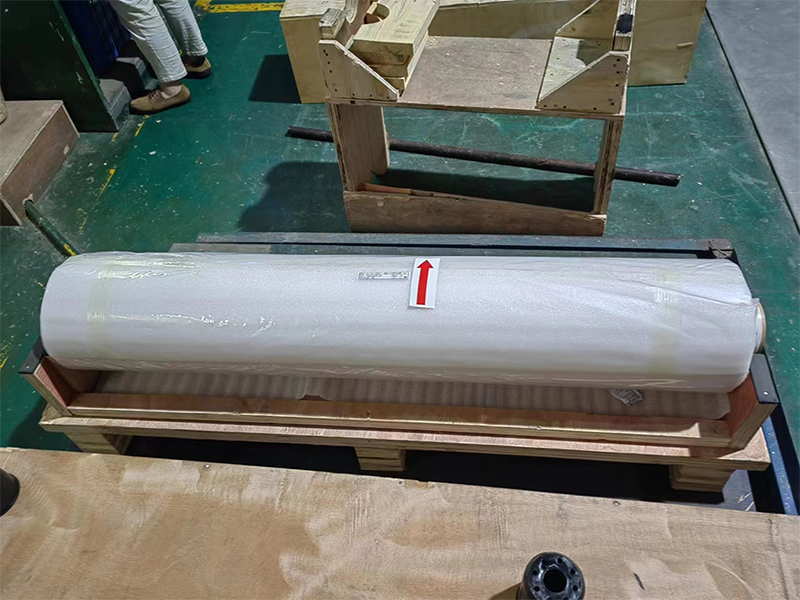

● Типичная толщина: 18UM 25 UM 35UM 50UM 70UM 105UM 140UM 150UM 175UM

● Типичная ширина : 914 мм 1000 мм 1100 мм 1290 мм 1350 мм , макс -1370 мм

● Идентификатор ядра: 76 мм/152 мм

● Типичная толщина: 18UM 25 UM 35UM 50UM 70UM 105UM 140UM 150UM 175UM

● Для Faradays Cage /Faraday Cage

● РЧ МРТ зажимание /МРТ (RF -экранированные комнаты)

● RFI/EMI Chembers/Builds

● Молния

● Аэрокосмическая, телекоммуникационные и медицинские устройства

Электролитическая медная фольга, используемая для экранирования, обычно состоит из высококачественного материала и обладает исключительной электрической проводимостью и магнитными экранирующими свойствами. Производство этой фольги включает в себя электролитический процесс, который гарантирует, что конечный продукт свободен от дефектов или примесей, что приводит к однородному материалу.

При использовании для экранирования эта электролитическая медная фольга обычно применяется в виде тонкого слоя или полоски к электронному оборудованию или компонентам для блокирования электромагнитных интерференций (EMI) и радиочастотных интерференций (RFI). Фольга действует как барьер и перенаправляет энергию от чувствительных электронных компонентов, в конечном итоге снижая риск искажения или потери сигнала. Более того, высокая проводимость медной фольги может служить наземным путем, что еще больше уменьшает эффекты EMI и RFI.

В целом, электролитическая медная фольга обеспечивает отличный экранирующий материал для обширного применения в таких отраслях, как аэрокосмическая промышленность, телекоммуникации и медицинские устройства. Его проводимость, свойства магнитной связи и простота использования делают его опцией для защиты продуктов и материалов.

1. Легкий (по сравнению с другими экранирующими материалами)

2. Медь с шириной 1320 мм или шире, может быть проще установлен, особенно для кровела, стены и пола.

3. Может использоваться либо с монолитным радиочастотным полом (устойчивостью к влаге) или модульным радиочастотным полом.

4. Медь служит вихревым током для защиты EMI.

5. RF Экранирование для комнат МРТ необходимо для предотвращения входа в РЧ -шума в МРТ -сканер и искажать изображение.

Три основных типа экранирования, используемые для МРТ, - это медь, сталь и алюминий. Медь, как правило, считается лучшей защитой для комнат МРТ.